In the ever-evolving world of automotive engineering, components like rubber bushings play a pivotal role in ensuring vehicle stability, comfort, and safety. At JAD, we specialize in high-quality aluminum control arms and complementary bushings designed for premium brands such as Mercedes-Benz, BMW, and Audi. In this article, we’ll explore the fundamentals of bushings, their benefits, and how modern vulcanization methods are revolutionizing the industry.

What Are Rubber Bushings and Why Do They Matter?

Rubber bushings are essential vibration-dampening components found in a vehicle’s suspension system. Typically made from durable rubber compounds bonded to metal sleeves or housings, they act as flexible joints between parts like control arms, stabilizer bars, and the chassis. Their primary functions include:

- Absorbing Vibrations and Noise: Bushings isolate road shocks and engine vibrations, reducing noise, vibration, and harshness (NVH) for a smoother ride.

- Enhancing Handling and Stability: By allowing controlled movement while maintaining alignment, bushings improve steering response and vehicle stability, especially during cornering or over uneven surfaces.

- Improving Durability and Safety: High-quality bushings withstand heavy loads, extreme temperatures, and corrosive environments, contributing to longer component life and safer driving.

Without reliable bushings, suspension systems can suffer from premature wear, misalignment, and increased fatigue, leading to costly repairs and compromised performance. At JAD, our bushings are engineered to meet these demands, backed by IATF 16949 certification and rigorous testing to ensure they perform under real-world conditions.

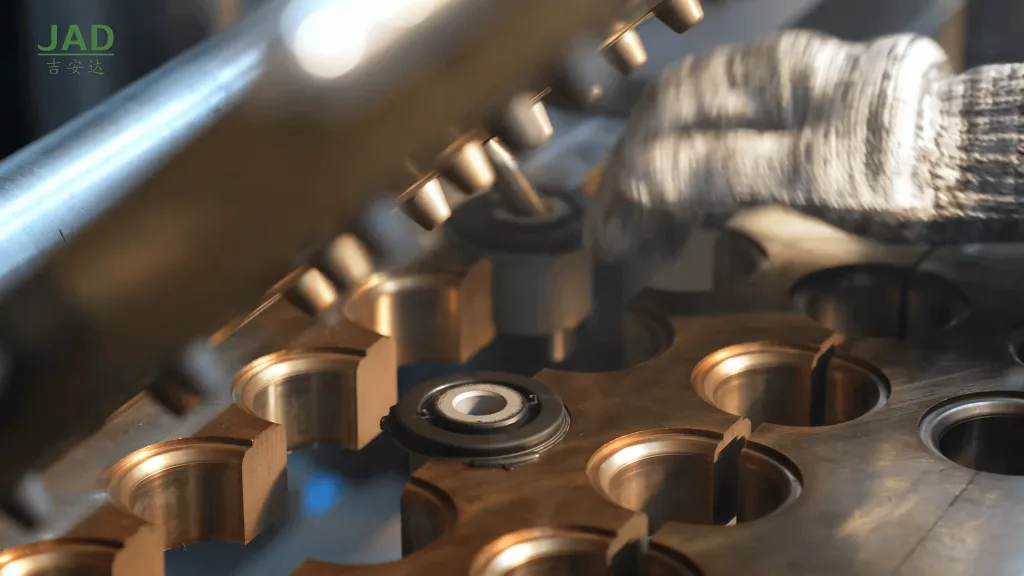

Innovative Manufacturing: Integral Vulcanization for Superior Performance

Traditional bushing installation often involves manual assembly with metal limit rings, which can introduce inconsistencies, stress concentrations, and potential corrosion points.

This process integrates the rubber bushing directly onto components like stabilizer bars during manufacturing. Key steps include:

- Preparation and Coating: After shaping and treating the metal bar (through heating, forming, heat treatment, and coating), an adhesive is applied to the bushing area or the rubber itself.

- Vulcanization: Using specialized machinery, the rubber is heated to 150-200°C for 1-5 minutes under pressure, creating a seamless bond. This eliminates the need for separate limit rings and manual insertion.

- Final Assembly: The result is a unified component ready for integration into the suspension system.

JAD employs similar advanced vulcanization techniques in our bushing production. Our workshop focuses on creating seamless rubber bushings that handle heavy loads and harsh environments while minimizing noise and enhancing ride quality.

Key Benefits of Integrally Vulcanized Bushings

Drawing from the principles in CN104690498A, integrally vulcanized bushings provide several advantages over conventional designs:

- Reduced Weight and Simplified Design: By eliminating metal limit rings, the overall component weight decreases, contributing to better fuel efficiency and easier handling during vehicle assembly.

- Improved Quality Control and Efficiency: Automated vulcanization replaces labor-intensive manual processes, ensuring consistent bonding and reducing manufacturing defects. This leads to higher production efficiency and more reliable products.

- Enhanced Durability and Longevity: The seamless integration minimizes stress concentrations, defects, and rust, significantly boosting fatigue resistance. As a result, bushings last longer—often exceeding traditional lifespans—and perform better in demanding conditions.

- Noise Reduction and Comfort: Post-installation noise issues, common in older designs, are virtually eliminated, providing a quieter, more comfortable driving experience.

- Environmental and Performance Gains: With better corrosion resistance and fewer failure points, these bushings support sustainable vehicle maintenance by reducing the need for frequent replacements.

At JAD, our bushings come with a 2-year/100,000-km warranty, reflecting our confidence in their superior performance. Whether for control arms or stabilizer systems, they deliver the reliability that B2B partners expect.

Applications in Modern Vehicles

Rubber bushings with integral vulcanization are ideal for high-performance vehicles from brands like Mercedes-Benz, BMW, and Audi. They excel in applications where precision and resilience are critical, such as:

- Suspension Control Arms: Providing flexible yet stable connections to absorb impacts.

- Stabilizer Bars: Enhancing roll resistance for better cornering dynamics.

- Chassis Mounts: Isolating vibrations to improve overall vehicle refinement.

By incorporating these advanced bushings, manufacturers can achieve vehicles that are not only safer and more efficient but also more enjoyable to drive.

Why Choose JAD for Your Bushing Needs?

As a source factory dedicated to aluminum control arms and bushings, JAD combines professional expertise with innovative processes to deliver top-tier products. Our focus on quality, from raw material inspection to final testing, ensures every bushing meets the highest standards.

If you’re a B2B partner looking to elevate your automotive components, we invite you to explore our range. Contact us today to inquire about prices, discuss custom solutions, or form a partnership. Let’s drive innovation together!