Introduction

The suspension system is the backbone of a smooth and safe driving experience, and car bushings are key players in this setup. These small components, nestled within the chassis, reduce wear between moving parts like control arms and shock absorbers while enhancing handling and comfort, this article delves into how bushings impact vehicle performance and their evolving role in modern automotive design.

What Are Car Bushings?

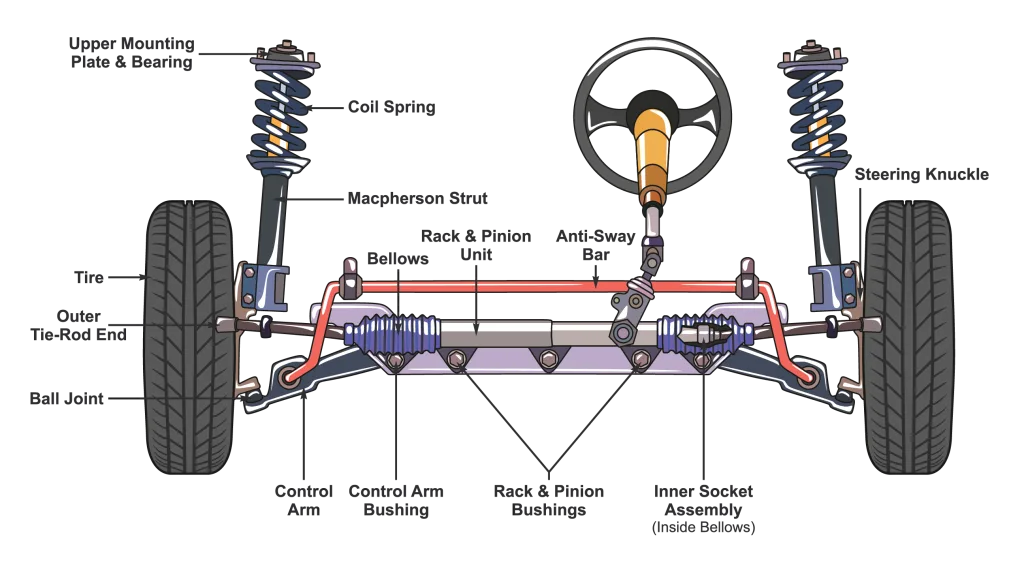

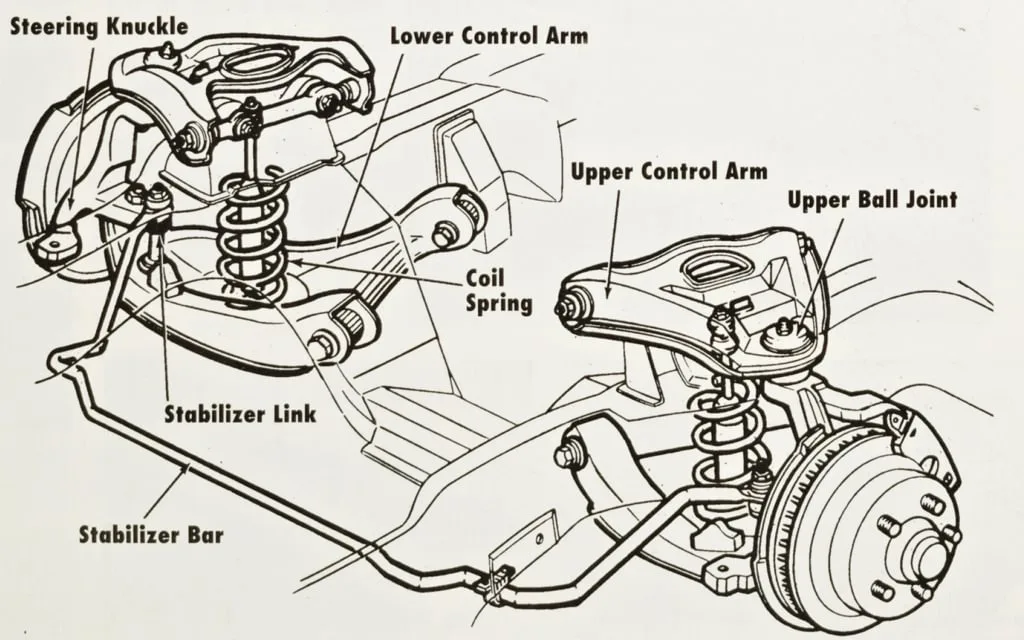

Car bushings are soft connectors found in the chassis, linking suspension components such as control arms and shock absorbers via shafts. Typically constructed with a tough steel outer shell and a flexible rubber or polyurethane core, bushings minimize friction, simplify replacements, and offer shock absorption. This dual-purpose design supports both durability and a refined ride.

The Impact of Bushings on Handling

Handling defines a vehicle’s responsiveness and stability, and bushings are critical to this:

- Friction Reduction: As a soft interface, bushings lessen wear between metal parts, ensuring smooth control arm movement.

- Vibration Damping: They absorb high-frequency vibrations on rough roads, complementing tires and shock absorbers to maintain stability.

- Noise Control: Rubber prevents metal-to-metal contact, muting harsh clunks to a subdued “thump,” enhancing driver control.

Bushings in the upper and lower control arms flex to adapt to road conditions, while some models feature them at shock absorber bases for added precision.

Bushings and Comfort

Comfort goes hand in hand with handling, and bushings contribute significantly:

- Shock Absorption: The rubber core deforms under pressure, cushioning impacts and reducing cabin vibrations.

- Complementary Support: While springs set ride firmness, bushings fine-tune comfort, especially in softer suspensions.

- Noise Reduction: By eliminating metal contact, bushings lower cabin noise, boosting passenger satisfaction.

Evolution with Hydraulic Shock Absorbers

Traditionally, bushing softness adjusted damping in suspension systems. However, hydraulic shock absorbers, with their oil-flow control, offer adjustable damping, lessening reliance on bushing flexibility. This advancement enhances shock absorption and handling, though bushings remain vital for wear reduction.

Maintenance and Replacement

To optimize bushing performance:

- Regular Inspections: Check for wear every 30,000 to 60,000 miles.

- Quality Replacement: Choose durable bushings from JAD for lasting results.

- Alignment Checks: Ensure proper alignment post-replacement for handling integrity.

Conclusion

Car bushings enhance handling by reducing friction and damping vibrations, while improving comfort through noise control and shock absorption. With hydraulic advancements, their role evolves, yet their value persists. At JAD, our premium bushings ensure top-tier performance for your vehicles or customers. Visit us today!

Call to Action:

Boost handling and comfort with JAD’s bushings. Contact us or visit our website for more!

References: