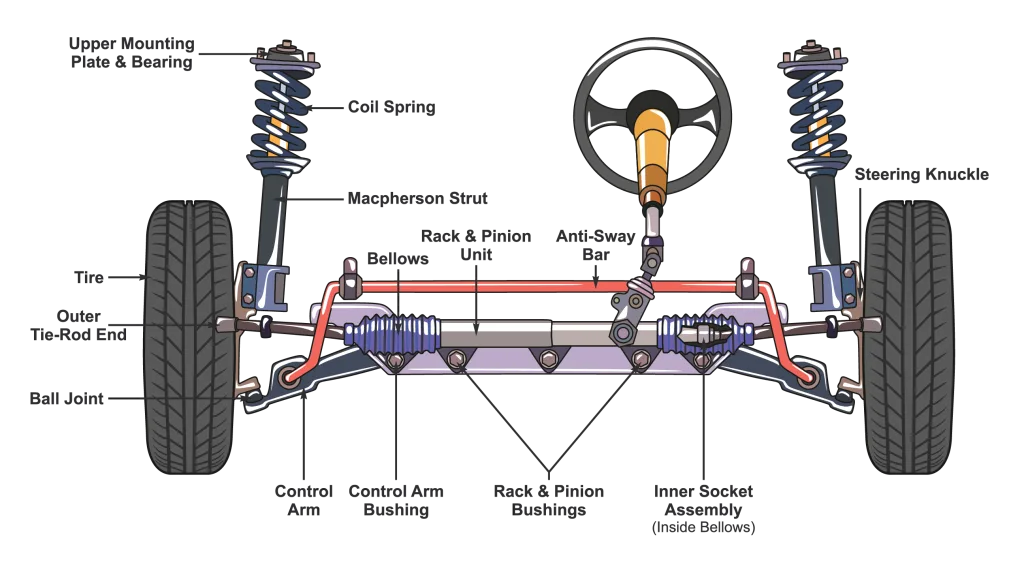

A vehicle’s suspension system ensures a smooth, safe ride, but rough roads can wear it out quickly. U.S. roads, rated D+ by the ASCE Infrastructure Report Card, accelerate damage to chassis parts, with issues appearing as early as 65,000 miles. Control arm bushings, critical for stability, are often overlooked despite their role in absorbing shocks. This article outlines 10 signs of suspension problems, emphasizing control arm bushings, to help repair shops and parts suppliers diagnose issues and maintain customer satisfaction.

What Are Control Arm Bushings?

10 Signs of a Bad Suspension

Suspension issues affect safety and comfort. Below are 10 common signs, with a focus on control arm bushings, to guide diagnostics:

1. Tie Rod and Tie Rod End Wear

- Symptoms: Wobbly wheels when lifted, trouble driving straight, uneven tire wear, rattling during turns, steering vibration, vague response.

- Impact: Forces constant steering corrections, reducing control.

- Solution: Inspect and replace worn tie rods or ends.

2. Steering Gearbox Issues

- Symptoms: Hard steering at low speeds, whining or knocking noises, loose steering, play in the linkage.

- Impact: Makes tight maneuvers difficult.

- Solution: Check and replace the gearbox if damaged.

3. Worn Ball Joints

- Symptoms: Clunking near wheels over bumps, wandering steering, loose chassis feel, alignment problems.

- Impact: Causes instability and uneven tire wear.

- Solution: Replace ball joints for precise handling.

4. Strut Bearing Damage

- Symptoms: Stiff or jerky steering, squeaking or clicking during turns, slow steering wheel return.

- Impact: Hinders smooth turning, especially at low speeds.

- Solution: Replace the entire strut top mount.

5. Strut Mount Rubber Deterioration

- Symptoms: Clicking or cracking during cornering, uneven ride height, abnormal steering noises, shaking.

- Impact: Can lead to shock absorber failure.

- Solution: Replace the strut mount assembly.

6. Stabilizer Bushing Wear

- Symptoms: Creaking over speed bumps, visible cracks in bushings.

- Impact: Causes noise and reduces stability.

- Solution: Replace bushings or apply lubricant for minor cracks.

7. Stabilizer Link Ball Joint Damage

- Symptoms: Clunking over speed bumps, often misdiagnosed after replacement due to improper installation.

- Impact: Affects ride smoothness and stability.

- Solution: Replace both left and right stabilizer links as a unit.

8. Control Arm Bushing Failure

- Symptoms: Sharp metallic knocking on rough roads, nodding or swaying during braking, inaccurate wheel alignment, visible bushing cracks.

- Impact: Exposed to heat, humidity, or salt, worn bushings reduce stability and cause tire wear. They absorb vibrations not handled by shocks.

- Solution: Inspect for cracks and replace bushings. In some regions, replacing only bushings is cost-effective, depending on control arm design.

9. Shock Absorber Problems

- Symptoms: Oil leaks, increased body sway, bumpy ride, uneven tire wear, knocking noises.

- Impact: Reduces driver confidence and comfort.

- Solution: Replace leaking or worn shock absorbers.

10. Sway Bar Link Wear

Solution: Replace sway bar links, ideally in pairs, to restore balance.

Symptoms: Rattling or clunking when hitting bumps, loose handling during turns, excessive body roll.

Impact: Compromises cornering stability and ride quality.

Why Control Arm Bushings Are Crtical

Control arm bushings prevent metal-on-metal contact, reducing noise and wear while ensuring stability. High-quality bushings, produced with advanced forging ( using 2000-ton presses) and tested for durability, withstand harsh conditions. For repair shops, reliable bushings reduce customer complaints. For suppliers, offering parts with a 2-year, 100,000-km warranty builds trust. Manufacturers producing 6,000 control arms daily ensure consistent supply for the aftermarket.

Diagnosing and Fixing Suspension Issues

Start by listening for noises like clunking or squeaking over bumps or during turns. Inspect parts when the vehicle is lifted:

- Control Arm Bushings: Check for cracks or protrusion. Replace if severely damaged to avoid instability.

- Other Parts: Look for play in tie rods, ball joints, or sway bar links.

- Professional Tools: Use coordinate measuring machines for precise diagnostics, as top manufacturers do.

Regular maintenance, like wheel alignments and avoiding rough roads, extends suspension life. For aftermarket professionals, sourcing parts from suppliers with robust production ensures quality and timely delivery.