Control arms are key parts of a car’s suspension system. They connect the wheels to the frame, ensuring a smooth and safe ride. Aluminum forged control arms are strong yet light, making them popular in the automotive aftermarket. This article explains the step-by-step process of making these parts. It’s useful for repair shops, parts suppliers, and car enthusiasts who want to understand the craftsmanship behind reliable suspension components.

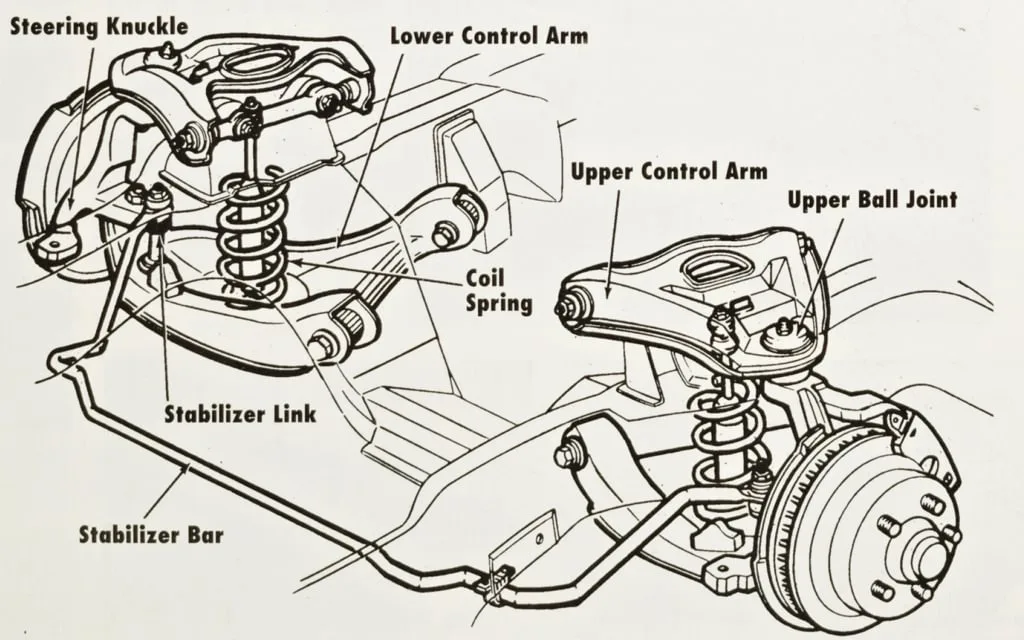

What Is a Control Arm?

A control arm, sometimes called an A-arm or wishbone, links the car’s chassis to the wheel hub. It lets the wheel move up and down while keeping it aligned. This ensures good handling and stability. Most cars have control arms in the front suspension, and some have them in the rear. Aluminum forged control arms are favored for their strength and low weight.

The Manufacturing Process of Integral Aluminum Forged Control Arms

Producing an integral aluminum forged control arm is a complex, multi-step process that demands advanced technology, skilled labor, and rigorous quality control. Below, we outline the key stages involved:

1. Design and Development

The journey begins with computer-aided design (CAD) modeling. Engineers create detailed digital prototypes of the control arm, specifying dimensions, geometry, and material properties. These models undergo simulations to ensure the part meets performance requirements, such as load-bearing capacity and fatigue resistance. This stage is critical for optimizing the control arm’s strength-to-weight ratio, a key advantage of aluminum forging.

2. Die Design and Production

Once the design is finalized, specialized dies (molds) are created to shape the aluminum into the desired form. These dies are precision-engineered tools, often made from high-strength steel, capable of withstanding the extreme pressures of forging. The die design process ensures that every curve and contour of the control arm is accurately replicated during production.

3. Aluminum Melting and Casting

The process continues with melting aluminum alloys in a high-temperature furnace. Aluminum is chosen for its lightweight properties and corrosion resistance, ideal for automotive applications. The molten aluminum is poured into molds to create rough castings, which serve as the starting point for the control arm’s shape.

Hot furnace

4. Heat Treatment

The rough castings undergo heat treatment to enhance the metal’s mechanical properties. This involves heating the aluminum to specific temperatures and cooling it in a controlled manner to improve strength, hardness, and durability. Heat treatment is essential for ensuring the control arm can withstand the stresses of daily driving, especially in demanding conditions.

5. Forging

The heat-treated castings are then placed in a forging press, where high pressure and temperature shape them into the final control arm form. Forging aligns the aluminum’s grain structure, significantly increasing its strength compared to cast or machined parts. This step is what makes integral aluminum forged control arms exceptionally robust and reliable.

6. Machining

After forging, the control arm undergoes precision machining to remove excess material and refine its shape. This step includes drilling holes for bushings and ball joints, ensuring tight tolerances for perfect fitment. Machining also creates mounting points and other features critical for the control arm’s integration into the suspension system.

7. Surface Treatment

To enhance durability and aesthetics, the control arm is subjected to surface treatments such as sandblasting, polishing, or anodizing. These processes smooth the surface, remove imperfections, and protect against corrosion, ensuring the part looks as good as it performs.

8. Quality Control and Inspection

The final step is rigorous quality control. Each control arm is inspected using advanced techniques, such as coordinate measuring machines (CMM) and non-destructive testing, to verify dimensions, structural integrity, and compliance with industry standards (e.g., ISO/TS 16949 for automotive parts). Only parts meeting these strict criteria are approved for distribution.

Why Quality Matters in Control Arm Manufacturing

The manufacturing process described above is not a simple task—it requires state-of-the-art equipment, highly skilled professionals, and a deep understanding of metallurgy and automotive engineering. Poorly made control arms can lead to issues like clunking noises, unstable handling, or premature tire wear, compromising vehicle safety and performance. For automotive aftermarket professionals, sourcing high-quality control arms ensures customer satisfaction, reduces returns, and enhances shop reputation.

High-quality control arms offer:

- Durability: Forged aluminum withstands extreme loads and harsh conditions, extending service life.

- Lightweight Performance: Aluminum reduces vehicle weight, improving fuel efficiency and handling.

- Precision Fitment: Tight tolerances ensure seamless integration with existing suspension systems.

Maintenance Tips for Control Arms

To maximize the lifespan of control arms, consider these maintenance practices:

- Regular Inspections: Check for signs of wear, such as cracked bushings or loose ball joints, every 12,000 miles or annually.

- Wheel Alignment: Ensure proper alignment to prevent undue stress on control arms.

- Avoid Harsh Conditions: Minimize driving on rough roads to reduce wear on suspension components.

- Quality Replacements: Choose control arms from reputable manufacturers to ensure reliability.

Conclusion

The production of integral aluminum forged control arms is a testament to the precision and expertise required in automotive manufacturing. From CAD design to final inspection, each step is meticulously executed to deliver components that enhance vehicle safety, stability, and performance. For parts suppliers and repair shops in the automotive aftermarket, understanding this process underscores the importance of choosing high-quality control arms to meet customer demands.

If you’re looking to source reliable suspension components or learn more about advanced manufacturing techniques, stay informed about industry standards and innovations. Share your insights or questions in the comments below!

References:

- Control Arm – Wikipedia

- Guide to Control Arms | MOOG Parts

- Aluminum Forging Process | Forging Knowledge

- Automotive Suspension Systems | SAE International