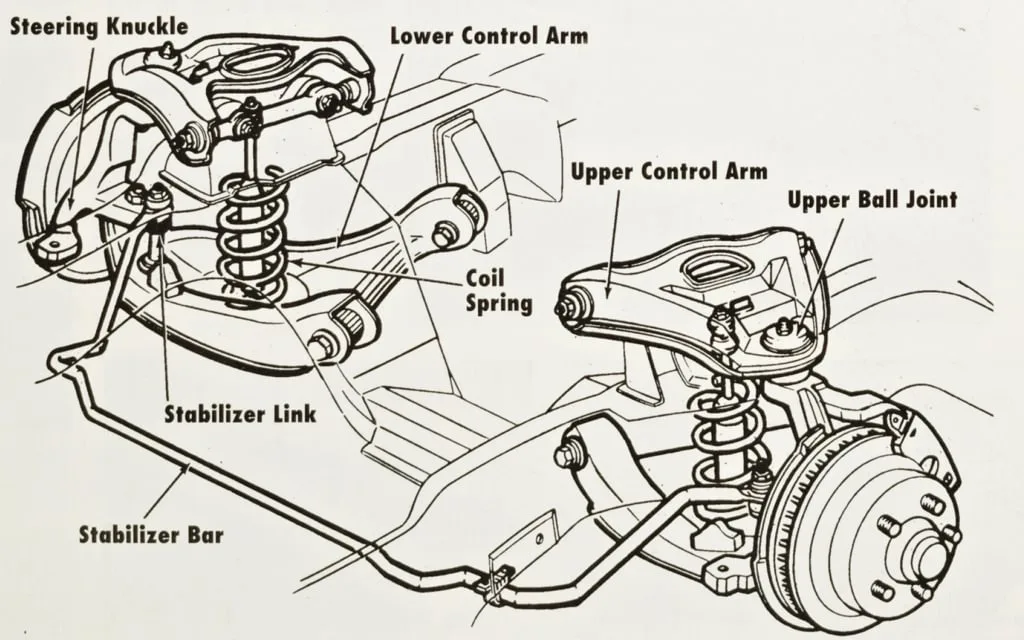

In the intricate world of automotive engineering, the suspension system plays a pivotal role in ensuring a smooth, safe, and comfortable driving experience. At the core of this system lies the control arm, a critical component that connects the wheel hub to the vehicle’s frame. This connection allows for controlled movement of the wheels, maintaining stability and handling precision.

What is a Control Arm?

A control arm, also known as an A-arm or wishbone, is a suspension link that connects the chassis of the vehicle to the wheel hub or knuckle. It allows the wheel to move up and down while keeping it aligned with the vehicle’s body. Control arms are typically found in the front suspension of most vehicles, and some vehicles may have them in the rear as well.

There are different types of control arms, including:

- Upper Control Arms: Located above the wheel assembly.

- Lower Control Arms: Positioned below the wheel assembly.

- Trailing Arms: Used in some rear suspension setups.

Each type serves a specific purpose in maintaining the vehicle’s stability and handling characteristics.

The Importance of Control Arms

Control arms are essential for several reasons:

- Wheel Alignment: They help maintain proper wheel alignment, ensuring that the tires wear evenly and the vehicle tracks straight.

- Stability and Handling: By controlling the motion of the wheels, control arms contribute to the vehicle’s stability during cornering and braking.

- Comfort: They absorb shocks from the road, providing a smoother ride for passengers.

- Safety: Properly functioning control arms are crucial for safe vehicle operation, as they prevent excessive wheel movement that could lead to loss of control.

Common Issues with Control Arms

Over time, control arms can experience wear and tear due to constant exposure to road conditions and environmental factors. Common problems include:

- Bushing Deterioration: The rubber or polyurethane bushings that connect the control arm to the frame can crack or degrade, leading to looseness and noise.

- Ball Joint Wear: The ball joints that connect the control arm to the wheel hub can wear out, causing clunking sounds and poor handling.

- Bent or Damaged Arms: Accidents or severe impacts can bend or damage the control arms, affecting alignment and performance.

Symptoms of Bad Control Arms:

- Clunking or Knocking Noises: Often heard when driving over bumps or during turns, typically due to worn bushings or loose ball joints.

- Unstable Steering Response: The vehicle may pull to one side or feel loose when turning, indicating a bent or misaligned control arm.

- Excessive Vibrations: Felt in the steering wheel or throughout the vehicle, especially at higher speeds, due to worn bushings or a bent control arm.

- Uneven or Premature Tire Wear: Misaligned wheels can cause tires to wear unevenly, a sign of potential control arm issues.

- Poor Handling or Suspension Performance: The suspension may feel less responsive or overly bouncy, struggling to maintain tire contact with the road.

Solutions: Choosing Quality Control Arms

When it’s time to replace control arms, selecting high-quality parts is crucial. Here’s what to look for:

- Material: Control arms made from durable materials like forged steel or aluminum offer better strength and longevity.

- Bushings: Opt for control arms with high-quality bushings that can withstand wear and provide a quiet, smooth ride.

- Ball Joints: Ensure the ball joints are robust and properly sealed to prevent premature failure.

- Fitment: Choose control arms that are specifically designed for the vehicle’s make and model to ensure proper fit and function.

At JAD, our control arms are engineered to meet or exceed OEM specifications. We use premium materials and advanced manufacturing techniques to produce control arms that deliver exceptional performance and durability.

Maintenance Tips for Control Arms

Control arms typically last around 100,000 miles or more, depending on driving conditions and maintenance. To extend their life and maintain optimal performance, consider the following tips:

- Regular Inspections: Have your suspension system inspected regularly by a professional mechanic to catch any signs of wear early.

- Avoid Harsh Conditions: Whenever possible, avoid driving on rough or unpaved roads that can accelerate wear on suspension components.

- Proper Alignment: Ensure your vehicle’s wheels are properly aligned to prevent undue stress on the control arms.

- Quality Replacements: When replacing control arms, choose high-quality parts from reputable manufacturers like JAD.

Control arms are a vital component of your vehicle’s suspension system, playing a key role in ensuring a smooth, safe, and enjoyable driving experience. By understanding their function, recognizing signs of wear, and choosing quality replacements, you can keep your vehicle performing at its best.

At JAD, we are committed to providing top-tier control arms that meet the highest standards of quality and reliability. Whether you’re a repair shop looking for dependable parts or a parts supplier seeking to offer the best to your customers, we have the solutions you need.

Visit our website to explore our range of control arms and learn more about how we can support your business.

Don’t let worn control arms compromise your vehicle’s performance. Upgrade to JAD’s premium control arms today and experience the difference. Contact us for more information or to place an order.

References: