As a masterpiece of industrial design, a car consists of three core parts: the powertrain, chassis system, and body. Among them, the suspension system belongs to the chassis system and is crucial for ensuring driving comfort and safety. This article will delve into the composition, working principles, classifications, and common faults of suspension systems, helping you fully understand this “core of vehicle shock absorption and stability.”

I. Core Functions of Suspension Systems: From History to Modern Times

The prototype of the suspension system can be traced back to the era of carriages. In early carriages, wheels were directly fixed to the body via axles, and road bumps were transmitted to the carriage without any buffering, resulting in extremely poor comfort. With technological development, the functions of modern suspension systems have evolved from simply “shock absorption” to multi-dimensional protection:

- Basic Function: Absorb road bumps, reduce body vibrations, and improve riding comfort;

- Safety Guarantee: Ensure the wheels remain in continuous contact with the ground, support the body weight, limit tire displacement, and enhance steering stability and braking effects;

- Structural Protection: Reduce wear on the body structure caused by road impacts and extend the vehicle’s service life.

II. Core Components of the Suspension System

The suspension system works through the collaboration of multiple components, each playing a key role. Here is an analysis of the core components:

1. Spring

The spring is the “load-bearing and buffering core” of the suspension system, mainly responsible for supporting the body weight and absorbing road impacts. Common types include:

- Coil Spring: Spiral-shaped, used in over 80% of modern vehicles, with strong adaptability, balancing comfort and handling;

- Leaf Spring: Composed of multiple superimposed steel plates, with strong load-bearing capacity, used in trucks and off-road vehicles;

- Air Spring: Adjusts hardness through air pressure, common in high-end models, and can dynamically adapt to road conditions;

- Torsion Bar Spring: Slender rod-shaped structure, currently less commonly used.

2. Shock Absorber

The shock absorber works with the spring to suppress the rebound vibration of the spring (not for load-bearing). When the vehicle passes over bumpy roads, the spring absorbs the impact and then produces reciprocating vibrations. The shock absorber quickly “calms” the vibrations through hydraulic or pneumatic damping force, preventing continuous body

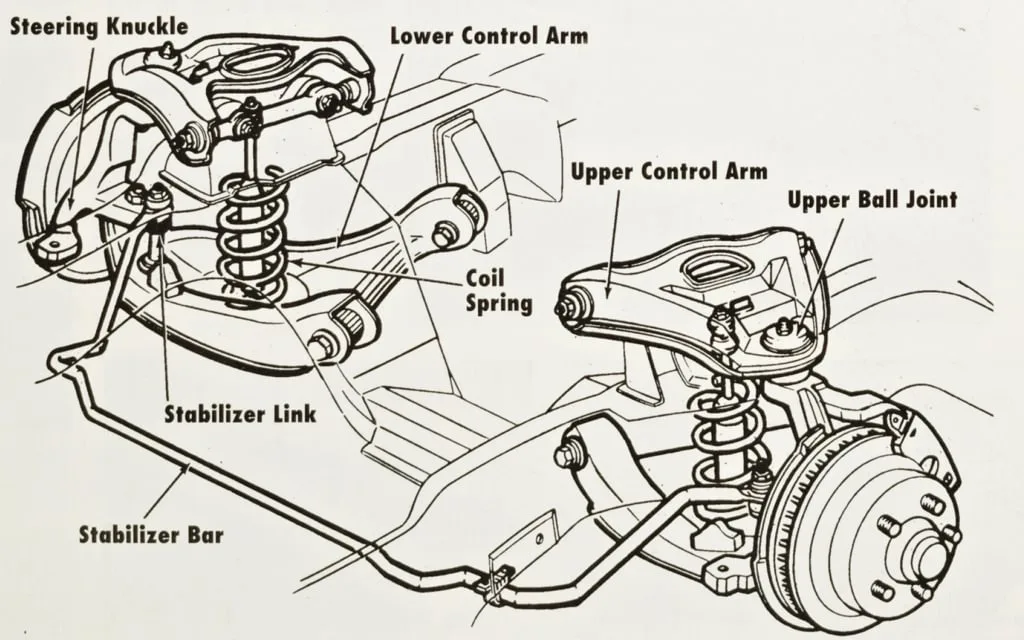

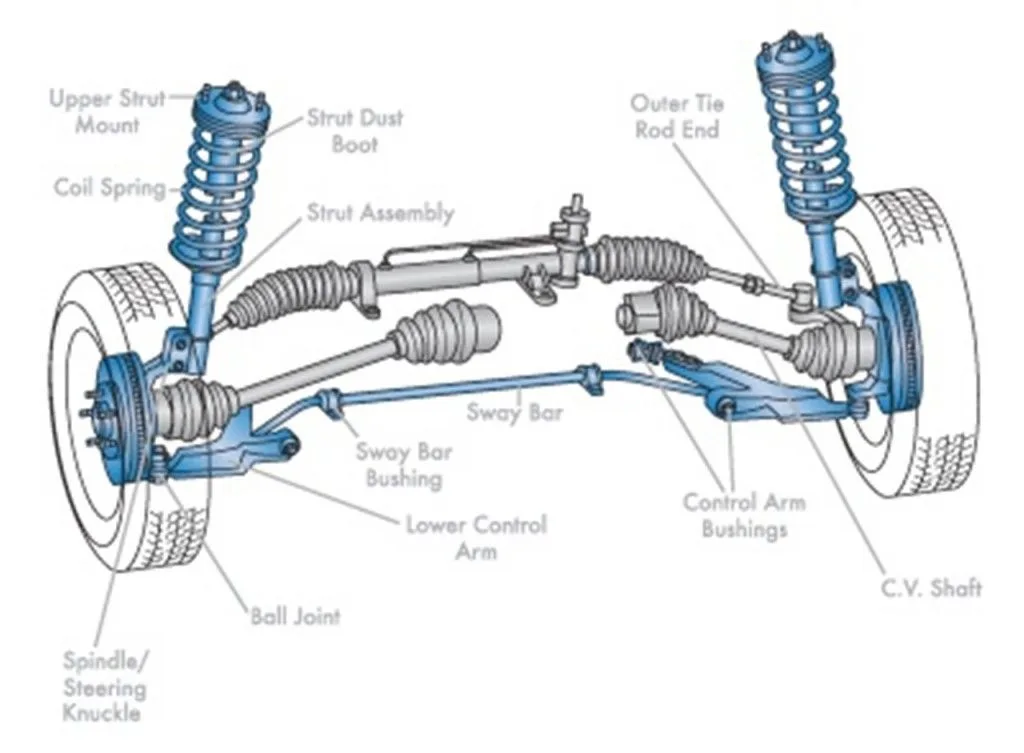

3. Control Arm

The control arm is the “bridge” connecting the body and the steering knuckle, achieving flexible connection through ball joints and bushings, and controlling the movement trajectory of the wheels. Its two ends are respectively connected to the body (bushing) and the steering knuckle (ball joint), ensuring the wheels maintain a stable posture during steering and braking.

4. Stabilizer Bar

The stabilizer bar is “U”-shaped, connecting the left and right wheels, and reduces body roll when the vehicle turns. When the body tilts, the stabilizer bar generates a reverse force through torsion, balancing the height of the wheels on both sides and improving steering stability.

5. Bushing and Ball Joint

- Bushing: A rubber ring connector that reduces friction and noise between metal components, absorbs vibrations, and improves comfort;

- Ball Joint: A spherical structure at the end of the control arm, similar to a human joint, allowing flexible rotation of the steering knuckle. It is a key component for ensuring steering function and needs to bear multi-directional forces from the tires.

III. Common Types of Suspension Systems

Suspension systems are classified in various ways, mainly based on structural design and functional characteristics. Common types include:

1. Classified by Structural Independence

- Independent Suspension: Left and right wheels do not interfere with each other, with excellent comfort and handling. Common types are:

- MacPherson Strut: Simple structure, low cost, widely used in family cars;

- Double Wishbone: Upper and lower double control arm design, precise handling, used in performance cars and luxury cars;

- Multi-Link: Controls wheel posture through multiple links, balancing comfort and handling, common in mid-to-high-end models.

- Non-Independent Suspension: Left and right wheels are connected rigidly (such as a solid axle), with a simple structure and low cost, used in trucks;

- Semi-Independent Suspension: Represented by the torsion beam, balancing cost and stability, common in the rear suspension of economical cars.

2. Classified by Front and Rear Axle Layout

The front and rear suspension designs of different models often vary due to functional requirements. For example:

- Front suspension: MacPherson, double wishbone, or multi-link are commonly used;

- Rear suspension: Torsion beams are commonly used in economical cars, while multi-link or double wishbone are used in high-end models.

IV. Common Symptoms and Solutions for Suspension System Failures

The suspension system is a “systematic project,” and damage to any component may affect overall performance. If the following symptoms occur, timely inspection and repair are required:

1. Abnormal Noise (Clunking/Rattling Noises)

A “clunking” or “rattling” sound from the chassis may be caused by wear of the shock absorber, control arm bushing, or ball joint. Control arm components of European cars are more prone to abnormal noise due to aging.

If the vehicle continues to bounce after passing over bumpy roads, it is mostly due to shock absorber failure (inability to suppress spring vibration). Under normal circumstances, the shock absorber should stabilize the body within 2-3 bounces.

2. Abnormal Wheel Alignment and Tire Wear

Damage to the control arm or ball joint will cause deviation of wheel alignment parameters, manifested as “pulling to one side” or unilateral tire wear. It is necessary to replace the damaged components in time and re-do the alignment.